Starch equipment factory 26 years, strive to be the first in the world

European technology Asian price

cassava starch equipment, tapioca powder equipment, garri processing equipment, 100 years equipment supplier

First, spiral cleaning conveyor. The spiral cleaning conveyor is one of the first manioc starch processing machine used. Its main purpose is to transport raw materials. It is usually made of stainless steel or carbon steel. It is characterized by easy operation, fast transportation and no leakage of materials.

Second, paddle washing machine. The paddle washing machine in the production line of manioca starch is mainly for removing other debris such as sand and soil on raw materials. The material of this manioc starch processing machine can also be made of carbon steel or stainless steel, which is characterized by high processing energy, good washing effect, low power consumption and stable operation.

Third, crutting machine and secondary rasper. These two manioc starch processing machine are indispensable equipment for crushing cassava, and are characterized by high processing energy, easy installation and maintenance, secondary crushing of cassava, high crushing rate, high starch yield, and energy saving.

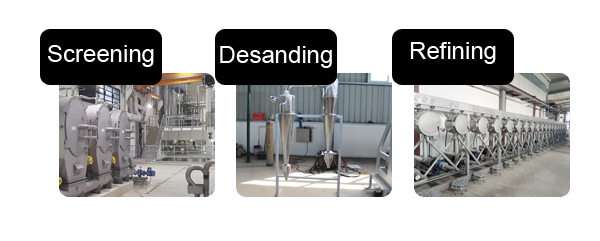

Fourth, centrifuge sieve & fine fiber sieve. These two manioc starch processing machine are both used for separating starch pulp and slag and removing fiber impurities. They have good separation effect, no mesh blocking, low cost and low energy consumption.

Fifth, sand remover. After processing the above machine, the cassava also need to use a sand remover to remove the sand and impurities in the pulp residue, which can be also regarded as perform secondary screening.

Sixth, hydrocyclone unit. The hydrocyclone is a manioc starch processing machine mainly removes protein impurities to ensure starch whiteness.

Sixth, peeler centrifuge & airflow flash dryer. After a series of previous work, wet starch need to be firstly dehydrated by manioc starch processing machine to 38%-40%, a desirable moisture for starch drying. Then it is also necessary to use a dedicated flash dryer to dry the starch to make the starch dry and easy to store.

PREV: concept note on production of cassava flour

NEXT:Period !